DIY Tips & Tricks

DIY TIPS & TRICKS

Choosing The Right Tile

Keep the following in mind before you choose floor tiles!

Durability and area application: consider the area, space or room you are choosing the tiles for: Is it an outside area or indoors, a wet area or a space where dirt may be brought in from the outside?

Colour and pattern

Texture and finish

Quantity of tiles: your design and overall decorating scheme will influence this. Are you installing diagonal or a pattern? Once you’ve measured the area to be tiled, it is wise to order 10-15% more to make up for cut tiles, and other breakages that may occur.

Grouting will also effect the overall result.

Price: it is more practical to look for flooring solutions that are going to offer value in the long term. Cheaper alternatives will not last as long, or wear as well.

Different Types of Tiles

Ceramic Tiles

Glazed Ceramic

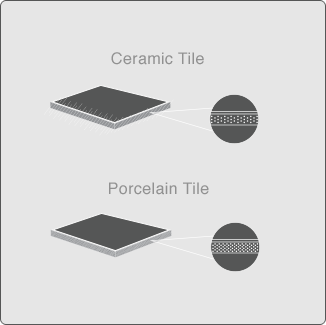

Glazed ceramic tiles consist of a ceramic body with a thin layer of glaze (glassy material) fired onto the surface. The glaze renders the tile waterproof, chemical resistant, fire-resistant and highly durable. These tiles are produced in various colours and textures ranging from matt to gloss finishes. Ceramic tiles have a water absorption of over 0.5%.

- Available in a wide range of beautiful designs and finishes

- Available in a range of sizes and formats

- Suitable for domestic applications

- Suitable for areas with high humidity such as bathrooms, toilets, laundries and kitchens

- Durable and long-lasting, easily cleaned and maintained

- Have an abrasion resistance (PEI) rating to ensure that the correct tile is chosen for the correct application

Unglazed Ceramic (Terracotta)

Terracotta literally means “fired earth” and a Terracotta tile (also known as a quarry tile) is made of fired clay, without a glaze. Tiles are usually the colours of the naturally occurring clays and range from browns to ochres to reds. The colours often vary from tile to tile as well. Ceramic and glazed porcelain tiles are available in our range which give the beautiful look of Terracotta with all the advantages of a glazed tile.

- Can be used internally or externally

- Suitable for "rustic" environments

- They have natural colours and beauty – no two tiles are the same

- Because Terracotta tiles are unglazed they are absorbent and will soak up liquids, greases, etc. For this reason, they must be sealed with a surface or penetrative sealant before use

- Terracotta tiles vary in size; wider grout joints of 10mm are recommended

Porcelain Tiles

Glazed Porcelain

A porcelain tile is manufactured from ceramic materials which are pressed harder and fired at a higher temperature than a ceramic tile. A glaze is applied in order to extend the range of decorative possibilities for the tile. These tiles are fired in the same way as unglazed porcelain with the addition of glaze.

- Exceptionally hard and durable

- Suitable for wall and floor, exterior and interior and all domestic applications

- Suitable for areas with high humidity such as bathrooms, toilets, laundries and kitchens

- Durable and long-lasting, easily cleaned and maintained

- Have an abrasion resistance (PEI) rating to ensure that the correct tile is chosen for the correct application

- Rectified available

Not Pie... Pei

- Pei 1 - for domestic areas with low traffic.

- Pei 2- for indoor and outdoor domestic areas with low traffic.

- Pei 3 - for indoor and outdoor domestic areas & domestic and light commercial use.

- Pei 4 - for areas indoor and outdoor & heavy-traffic areas.

- Pei 5 - for all domestic & commercial heavy-traffic areas.

Unglazed Porcelain

Porcelain tiles are made with ceramic materials which are pressed harder and fired at a higher temperature than glazed ceramic tiles. The materials in them melt (vitrify) into a glassy material which has a water absorption of less than 0.5%. Unglazed porcelain can be polished to a high gloss and the tile is the same colour all the way through (full body) or the tile can be a double-loaded tile (two layers, the bottom layer being the body and the top layer being the design, pressed together to form a single tile).

- The tile is the same colour all the way through – no glaze to chip off

- Very hard and durable

- Rectified edges are available. This is where a few mm are ground off the edge of the tile to make the sizing exact

- Available in a range of sizes and formats

- Suitable for wall and floor especially external areas

Polished porcelain (nano treated)

Porcelain tiles are made with ceramic materials which are pressed harder and fired at a higher temperature than glaze ceramic tiles. The materials melt (vitrify) into a glassy material which has a water absorption of less than 0.5%. Nano treatment is a process of treating the surface of the tile with organic nano particles. The particles combine with the tile substance to form a nano film of high density and stability. It increases the sheen of the tile, enhances the colour and provides improved protection against staining.

- Crystal-clear effect. Lustre on normal polished porcelain is 55-70%

- Nano tile is 85-90% - close to a mirror finish

- Durable and anti-dirt. No micro-pore staining as the nano particles completely fill the pores

- Anti-bacterial superb hardness - equivalent to granite, making it hardwearing and long-lasting. Green and

- environment-friendly

- Does not require harsh and harmful cleaning materials

Natural Stone

Natural stone tiles are cut from natural materials such as sandstone, slate, marble and travertine, etc. The stone is quarried from the ground and cut and shaped to size. The stone can be in its natural state or it can be polished. Marble is usually polished to bring out the colour variations.

- Natural stone has status value. It is normally more expensive than other materials, but for customers who are looking for ‘the real thing’ nothing else will do!

- Being a natural product, there are variations in colour pattern, and surface

- Suitable for wall and floor, interior or exterior and all domestic applications

- It is porous, which means it will stain unless properly sealed

Inkjet digital printing

Inkjet Ceramic Tiles are produced from the same ceramic materials as normal ceramic tiles, but instead of being decorated with glazes, they are printed with special inks to create photo-realistic images on the surface of the tile. Much like the picture on your television screen, the graphics on tiles are made up of millions of small dots of colour. Digital printing that brings you the most realistic image possible, on a tile.

The surface is then coated with a clear glaze to protect the design. A good inkjet design offers the benefit of variability. Ideally there should be between eight and ten different ‘faces’ for each design. This means that there should be no repeated tiles within a two square meter space.

- Inkjet tiles offer a low-maintenance solution in comparison to natural materials such as marble, stone or wood as no sealing or deep cleaning is required

- Life-like designs resulting in ‘the look’ without the expense of ‘the real thing’

- With appropriate ventilation, ceramic tiles prevent the formation of mould

- The colours are more realistic with finer detail than traditionally produced tiles

- Can be cleaned with a damp cloth