Polyurethane Flooring

June 2023

5 Steps to a perfect Commercial resin flooring system

Featured project: Wonderboom Junction Spar

Have you ever been in awe of a seamlessness resin flooring system and wondered how tough it was to install? Tile Africa Commercial recently installed 1850m2 of ASP STB EPOXY SCREED Power trowel flooring system in the new flagship Spar at Wonderboom Junction. We interviewed our expert, Tyrone Little, for these 5 steps to apply the ideal finish for your seamless retail space that is both durable and easy to clean.

Step 1: Identify the product to be used.

The product used to create 1850m2 of this elegant, functional & hard-wearing RETAIL floor is the ASP STB EPOXY SCREED Power trowel flooring system. This is made up of custom 1.6mm colored glacial quartz and a clear high strength epoxy resin placed and finished at approximately 3-4mm thick. The ASP STB EPOXY SCREED was specifically colored and mixed to fulfill the design teams’ vision for the store.

Step 2: Surface Preparation.

Proper surface preparation is crucial and the basic building block for a successful installation of any seamless resin system is to ensure you remove the latency of the concrete to ensure you have a good mechanical bond. The concrete substrate should be clean, free of contaminants, and structurally sound. All existing concrete must be fully cured and must have a minimum compressive strength of 25 Mpa. It may involve shot blasting &diamond grinding to achieve the desired surface profile.

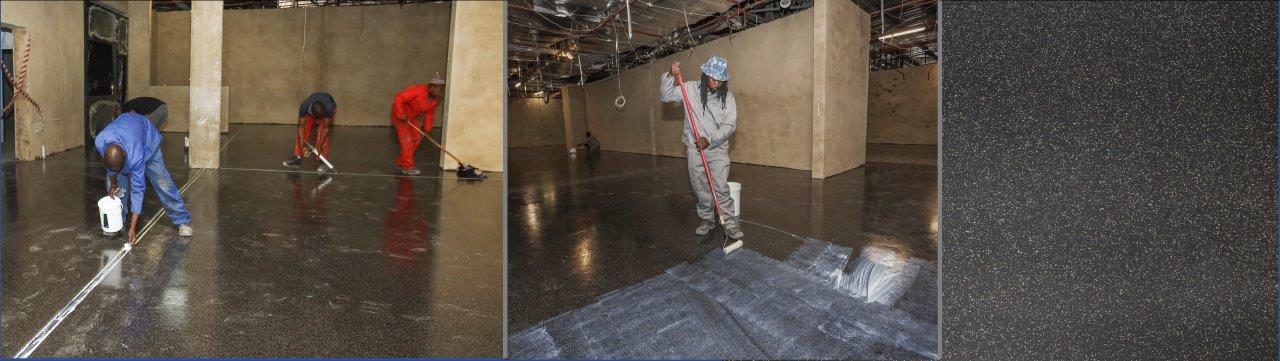

Step 3: Priming the Surface and Applying of the Epoxy Mortar.

After the substrate/concrete has been grinded the ASP epoxy primer is applied to the prepared substrate. The primer helps improve adhesion and seals off the concrete to help reduce any potential gassing coming through from the concrete underneath. By scattering silica quartz into the wet primer it ensures the slurry is held in place before the power trowelling starts, it also acts as a guide on maintaining the required thickness of the final floor thickness. Thereafter the ASP STB EPOXY SCREED slurry is poured and spread over the primed substrate using a trowel or squeezy. The thickness of the mortar layer should be consistent and uniform throughout the area before the coloured quartz is manually broadcasted into the epoxy mortar.

Step 4: Adding the colored Quartz.

Once the epoxy slurry is spread and fully saturated by the coloured quartz, a small power trowel machine is used to compacted and achieve a smooth, level, and dense surface. The power trowel helps to embed the coloured quartz into the epoxy slurry to create a smooth and level surface. The coloured quartz adheres to the surface and adds texture and visual appeal.

Step 5: Application of Topcoat / Termination & Repair.

Once the power trowel epoxy screed is cured the screed is de-nipped using a steel blade before a clear epoxy seal coat is applied. This fills in any uneven areas and is used to bring the color of the floor to life. A matt clear seal coat is applied to the surface as a final layer to protect it and increase durability after the epoxy seal coat has sufficiently cured. Due to foot traffic and scuffing, the matt coat can be used to rejuvenate the floor in high traffic areas. This can be done at night to limit down-time during trading hours, as per the manufacturer’s instructions.

ASP STB EPOXY SCREED power trowel flooring system cures in excess of 70mPa and is designed to withstand high levels of foot traffic and mechanical abrasion. The power trowelling process creates a dense and smooth surface that is resistant to wear and abrasion, making it suitable for heavy industrial and commercial applications.

For further information on our installation service and our fit for purpose solutions contact Tyrone Little: https://www.linkedin.com/in/tyrone-little-365797101/ or visit our website: https://www.tileafrica.co.za/commercial.